Simplified variable valve timing

Description: Electro-Mechanical Associates, Inc. has successfully completed a study for the Navy to determine the feasibility of a two step lifter (Smart Lifter) for improving Diesel fuel economy. It is estimated that a fuel economy improvement of 5% or more is likely using a two step valve lifter on the intake and exhaust valves to vary valve timing. Smart lifter is lower cost and more easily implemented than other variable valve timing (vvt) mechanisms.

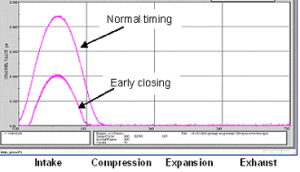

Smart lifter on the intake valve obtains cold startability by using two-step lifters to close the intake valves early for increased effective compression ratio. For high speed Diesels, the intake valve closes between 40 and 60 degrees after bottom center. This reduces the effective compression ratio significantly. During cold cranking, the intake valve, closing is moved closer to bottom center of the intake stroke, thereby providing the full design compression ratio. Smart lifter keeps the valve landing speed within the durability limit of the valves. Once the engine is started and warmed up, the valve timing then follows the camshaft profile.

When Smart Lifter is applied to the exhaust valve, it is projected that early valve closure will increase internal EGR which improves cold starting by retaining heat and fuel for the next combustion cycle that would normally be expelled from the cylinder.

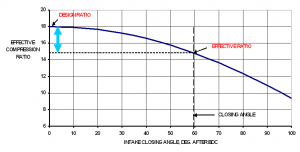

Background: Diesel compression ratios are normally set high (between 16:1 and 23:1) for cold starting, but data show optimum fuel efficiency and emissions occur at compression ratios below 14:1. Also, reducing the compression ratio by 10% (for example) in turbo-engines allows a 20% increase in torque for a given peak cylinder pressure. With appropriate controls, Smart Lifter allows lower compression ratio, improved fuel economy, and lower emissions without loss of cold startability.

Graph shows the effect of intake valve closing angle on effective compression ratio. (Click to enlarge)

Who will benefit: Engine manufacturers looking for a low cost alternative to variable valve timing as well as the Diesel retrofit industry will benefit from this lifter technology.

Benefits and features of Smart Lifter technology:

• Improved torque on turbo-engines without exceeding pressure limits

• Reduced engine friction, wear and noise

• Reduced CO2, NOx and particulate emissions

• Works with pushrod and overhead cam engines

• Little or no modification of the block or heads

• Patent pending

For more information, contact Electro-Mechanical Associates, Inc. 734.995.2455